Suchen Sie nach kundenspezifischen Kabelbäumen und Kabelkonfektionen?

Senden Sie Ihre technischen Anforderungen und Projektdetails, und unser Entwicklungsteam wird Ihre Anfrage prüfen und innerhalb von 24 Stunden antworten.

-

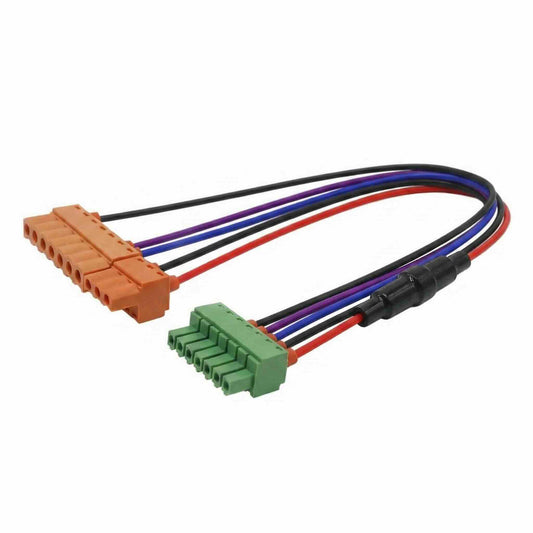

Phoenix Contact 3-polige und 7-polige Schraubklemmenleiste - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

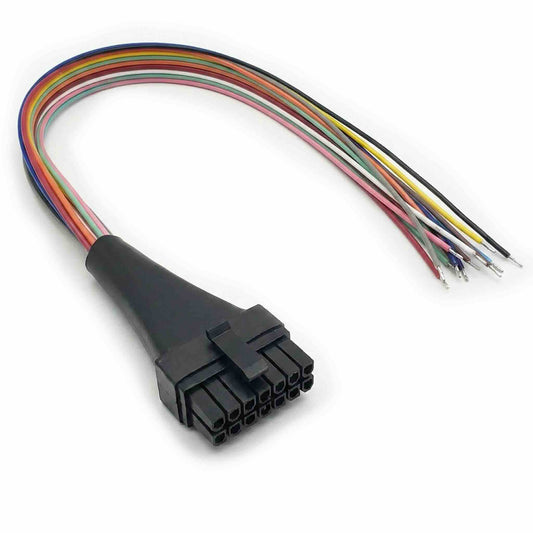

TE 43025-1400 14-Pin Micro-Fit 3.0 zu offenem Ende - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M12 4-polige männliche Panelmontage zu JST XH2.54 - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

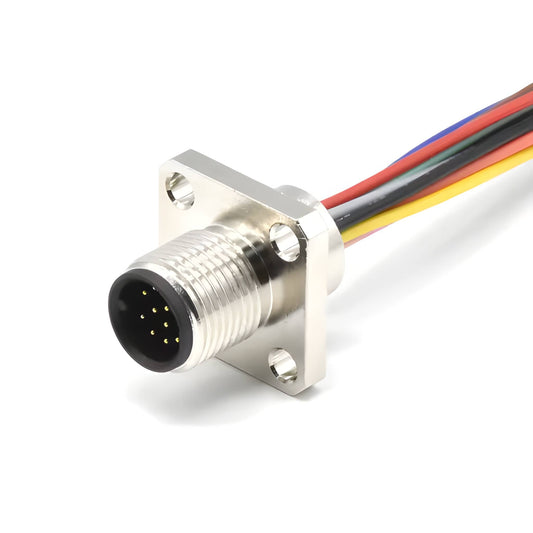

M12 12-polige männliche Frontmontage-Buchse zu JST PH1.25 - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M7/8'' Weibliche 3-polige Paneleinbaubuchse zu offenem Ende - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M7/8'' Männlicher 4-poliger Panelsteckverbinder zu offenem Ende - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M8 4-polige A-Code Buchse gerade Sensorkabel - Kundenspezifische wasserdichte Kabelanordnung

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M12 3-polige gerade männliche Anschlüsse an Ringklemme - Kundenspezifische wasserdichte Kabelanordnung

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

RJ45 4-Pin Gerade zu Rechtwinklig Ethernet-Kabel - Benutzerdefinierte wasserdichte Kabelanordnung

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M12 8-Pin Stecker männlich zu RJ45 Industrielle Ethernet IP67 Kabel - Benutzerdefinierte wasserdichte Kabelanordnung

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M8 3-Pin Weiblicher Paneleinbau-Steckverbinder mit offenem Ende - Benutzerdefinierte wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M12 5-Pin Weiblicher Frontmontage-Panelanschluss zu offenem Ende - Kundenspezifische wasserdichte Kabelanordnung

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M12 8-polige Buchse zu Anschlussklemmengehäuse - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M12 12-polige Buchse zu Anschlussklemmengehäuse - Kundenspezifische wasserdichte Kabelbaumkonstruktion

Normaler Preis $5.00 USDNormaler PreisStückpreis pro -

M5 4-polige Steckverbindung

männlich/weiblich

für Einbau in Gehäuse

mit offenem Kabelende - Kundenspezifische wasserdichte Kabelbaum-BaugruppeNormaler Preis $5.00 USDNormaler PreisStückpreis pro -

M12 12-polige Stecker/Buchse Quadratischer Flansch Panelmontage zu offenem Ende - Kundenspezifische wasserdichte Kabelbaumkonfektionierung

Normaler Preis $5.00 USDNormaler PreisStückpreis pro

Können Sie das genaue Kabel nicht finden, das Sie benötigen?

Auf unserer Website sind nur ein Bruchteil unserer Fähigkeiten aufgeführt. Wir fertigen Tausende von kundenspezifischen Kabelkonfektionen und Kabelbäumen, die nicht online gezeigt werden. Laden Sie Ihre Zeichnung oder Spezifikationen hier hoch, und wir werden sie für Sie anfertigen.

Manufacturing Standards & Capabilities

ISO 9001 Certified Factory

TeleWire Technology operates under strict ISO 9001 Quality Management Systems. Every production run undergoes rigorous IQC (Incoming Quality Control) and IPQC (In-Process Quality Control) to ensure consistent, OEM-grade reliability for global supply chains.

IPC/WHMA-A-620 Compliance

Our assembly technicians adhere to IPC/WHMA-A-620 standards for cable and wire harness fabrication. We guarantee precision crimp height, pull-force retention, and strain relief integrity for high-vibration automotive and industrial environments.

100% Electrical Testing

Zero defect policy. 100% of finished assemblies undergo automated testing for continuity, shorts, and mis-wiring. For critical safety applications, we provide advanced VSWR testing, high-pot testing, and insertion force validation.

Custom Component Sourcing

We source genuine connectors from Amphenol, TE Connectivity, Molex, and JST, or provide cost-effective, high-quality equivalents to meet your BOM targets. Our engineering team supports rapid prototyping with low MOQs and fast turnaround times.

Have 2D or 3D drawings ready?

Talk to our engineering team for immediate design validation and DFM (Design for Manufacturing) support.