Trusted by Industry Leaders Worldwide

Delivering zero-defect reliability for mission-critical testing.

-

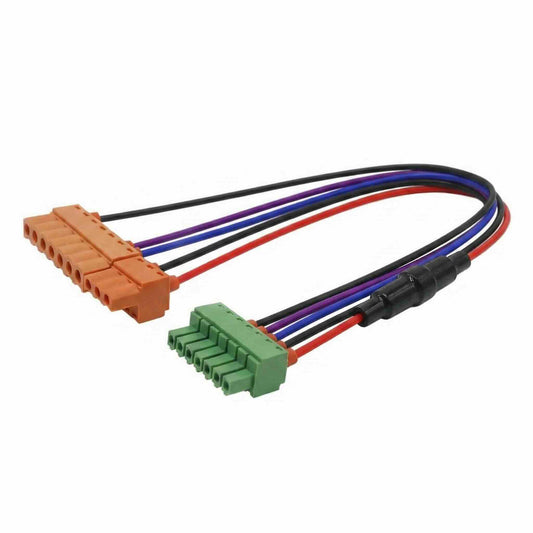

Phoenix Contact 3-stifts och 7-stifts skruvplintblock - Anpassad vattentät kabelknippe-montering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

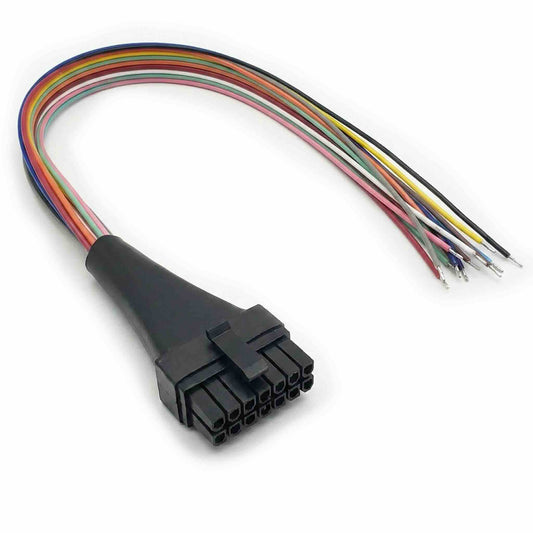

TE 43025-1400 14-Pin Micro-Fit 3.0 to Open End - Custom Waterproof Wire Harness Assembly

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M12 4-Pin Male Panel Mount to JST XH2.54 - Custom Waterproof Wire Harness Assembly

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M12 12-Pin Male Front Mount Socket to JST PH1.25 - Custom Waterproof Wire Harness Assembly

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M7/8'' Kvinnlig 3-stifts panelmontering till öppen ände - Anpassad vattentät kabelknippe

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M7/8'' Hankontakt 4-stifts panelmontage till öppet ände - Anpassad vattentät kabelknippe

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M8 4-Pin A-Code Female Straight Sensor Cable - Custom Waterproof Cable Assembly

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M12 3-stifts rak hane till ringkontakt - Anpassad vattentät kabelmontering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

RJ45 4-stifts rak till vinklad Ethernet-kabel - Anpassad vattentät kabelmontering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M12 8-stifts hane till RJ45 industriell Ethernet IP67-kabel - Anpassad vattentät kabelmontering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M8 3-stifts honkontakt för panelmontering till öppet ände - Anpassad vattentät kabelknippe

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M12 5-stifts honkontakt för frontmontage till öppen ände - anpassad vattentät kabelmontering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M12 8-stifts honkontakt till terminalhus - Anpassad vattentät kabelknippe-montering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M12 12-stifts honkontakt till terminalhus - Anpassad vattentät kabelknippe-montering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

M5 4-stifts hane/honpanel monteringskontakt till öppen ände - anpassad vattentät kabelknippe

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per -

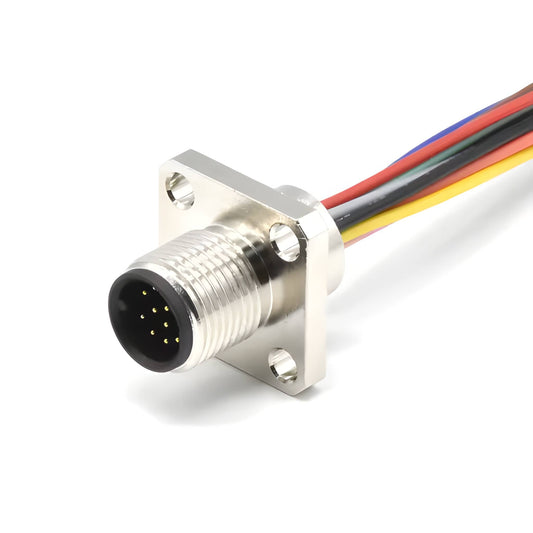

M12 12-stifts hane/hona fyrkantig fläns panelmontage till öppen ände - anpassad vattentät kabelknippe montering

Ordinarie pris $5.00 USDOrdinarie prisEnhetspris per

Can't find the exact cable you need?

Our website lists only a fraction of our capabilities. We manufacture thousands of custom cable assemblies and wire harnesses not shown online. Upload your drawing or specs here, and we will build it for you.

Manufacturing Standards & Capabilities

ISO 9001 Certified Factory

TeleWire Technology operates under strict ISO 9001 Quality Management Systems. Every production run undergoes rigorous IQC (Incoming Quality Control) and IPQC (In-Process Quality Control) to ensure consistent, OEM-grade reliability for global supply chains.

IPC/WHMA-A-620 Compliance

Our assembly technicians adhere to IPC/WHMA-A-620 standards for cable and wire harness fabrication. We guarantee precision crimp height, pull-force retention, and strain relief integrity for high-vibration automotive and industrial environments.

100% Electrical Testing

Zero defect policy. 100% of finished assemblies undergo automated testing for continuity, shorts, and mis-wiring. For critical safety applications, we provide advanced VSWR testing, high-pot testing, and insertion force validation.

Custom Component Sourcing

We source genuine connectors from Amphenol, TE Connectivity, Molex, and JST, or provide cost-effective, high-quality equivalents to meet your BOM targets. Our engineering team supports rapid prototyping with low MOQs and fast turnaround times.

Have 2D or 3D drawings ready?

Talk to our engineering team for immediate design validation and DFM (Design for Manufacturing) support.